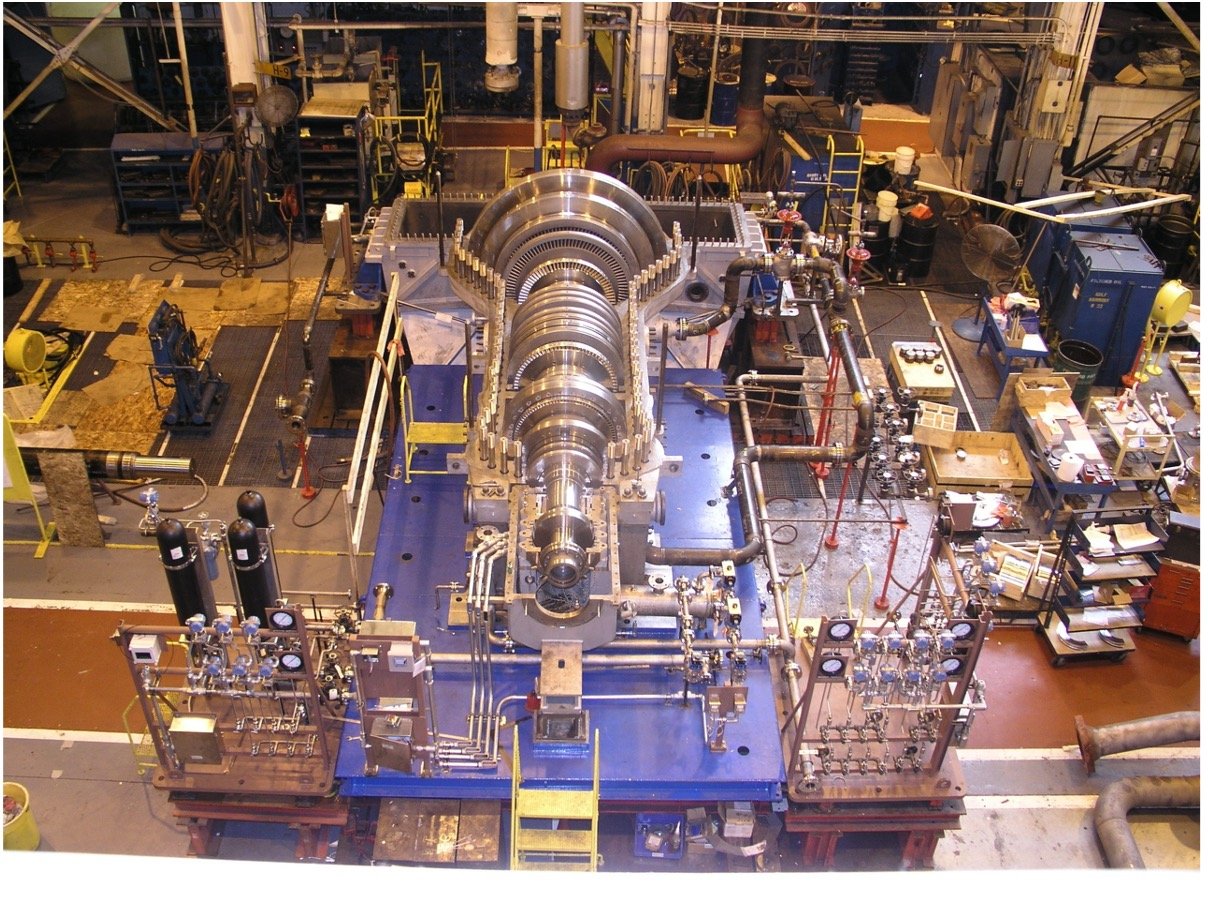

65 MW Cogeneration Turbine

Project Description:

Our pulp and paper client identified an opportunity to optimize steam resources and increase revenue by installing a 65 MW condensing steam turbine/generator set. Mill-wide steam consumption was reviewed and maximum efficiency gained by converting several turbine drives to electric; optimizing steam generating boilers; and installing the turbine generator & associated equipment. The scope of the TG project involves turbine, new condenser, new mill-wide steam piping, cooling towers, electrical switchgear, controls, engineering and implementation assistance.

Scope of Work:

SDE and Binnington Development Corporation collaborated to provide definition-level engineering services to develop a preliminary process design and cost estimate for this project. Work includes purchase and installation of a TG set and ancillary equipment; process control systems; grid interconnection and protection, major switchgear and substation. Work was completed on an EPCM basis for the equipment specification & procurement, detailed process mechanical, electrical instrumentation, and controls engineering, with ongoing project/construction management support.