No. 2 Paper Machine Fourdrinier Table Rebuild

PROJECT DESCRIPTION:

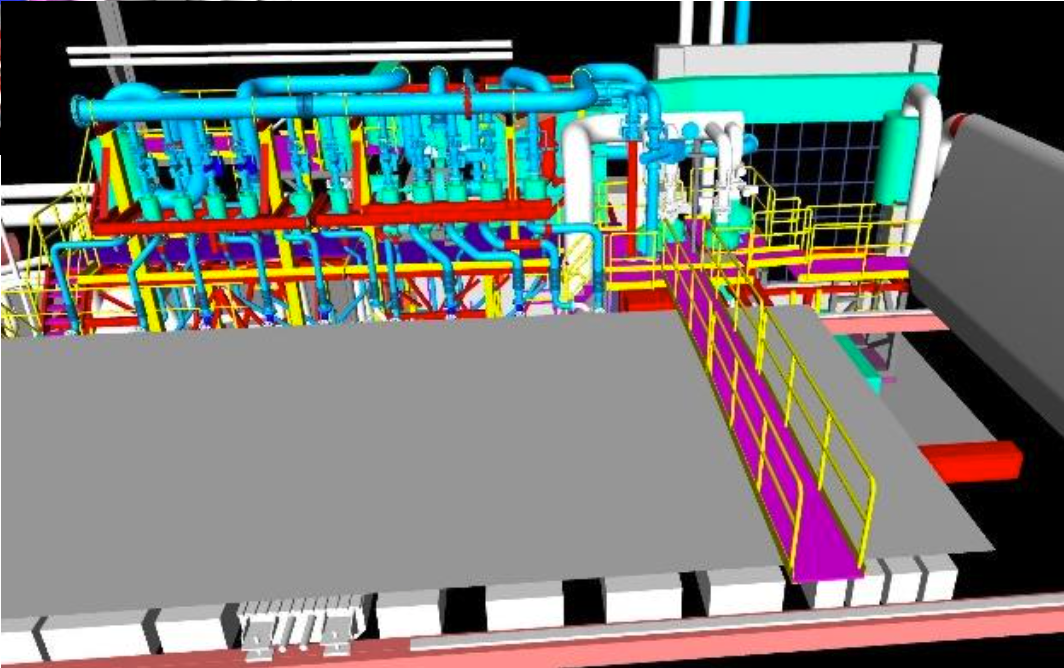

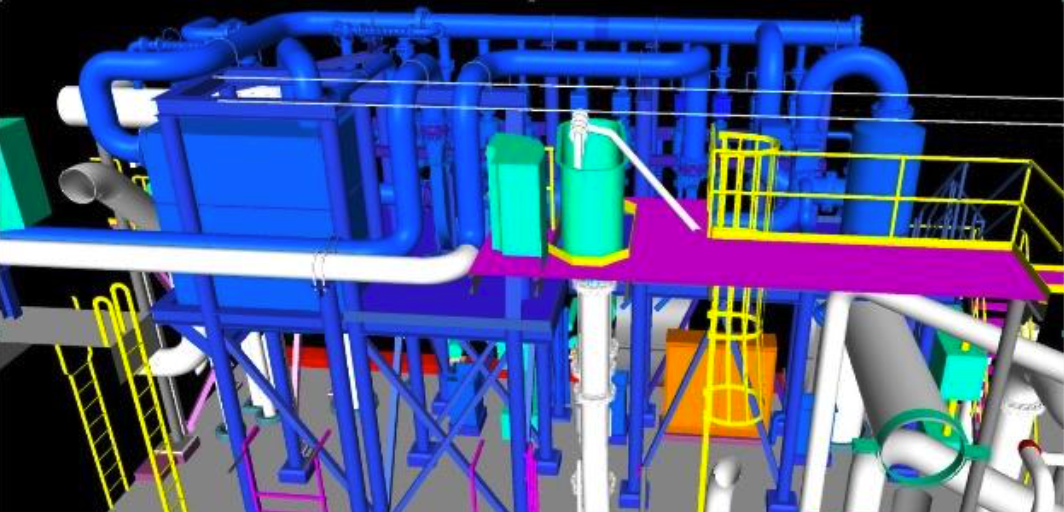

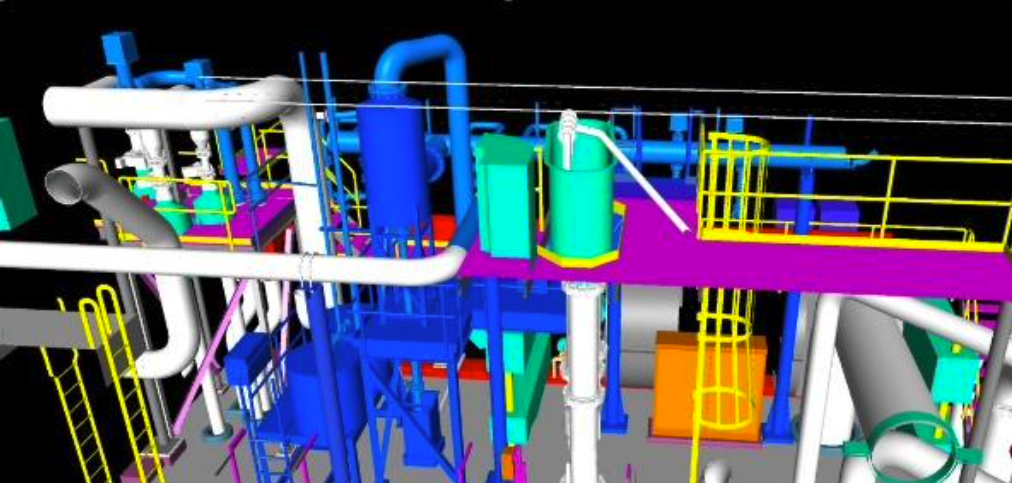

This project includes the detailed design for the No. 2 paper machine fourdrinier table rebuild at Port Townsend Paper. Sacré-Davey staff reviewed the documentation provided by the technology provider, IBS, and integrated the system requirements within the mill. We provided a scope of work construction package that described and detailed the multidisciplinary work and specific requirements for contractor installation.

SCOPE OF WORK:

The Sacré-Davey team produced an IFC (issued for construction) package that included all work necessary to install ancillary equipment for proper operation of the rebuilt fourdrinier table. This included process, mechanical, electrical and instrumentation/control.

CHALLENGES:

Paper mill turnarounds are extremely important time periods each year for installation projects. As this project impacted a very important financial asset of the facility, Sacré-Davey was asked to carefully design around PM2's operations to make full use of the time period before and after the mill's outage.

A secondary challenge was utilizing the limited wet end spacing for installation of larger and more complex equipment configurations.

SOLUTIONS:

As part of our scope of work packages, Sacré-Davey deliberately separated the pre-outage work into its own standalone package, facilitating contractors to begin the construction/demo work weeks ahead of the turnaround. Additionally, Sacré-Davey designed a more vertically integrated mechanical system that could be fabricated as a full system off-site and installed in place via crane.

ACHIEVEMENTS:

Sacré-Davey successfully compiled all aspects of the design packages utilizing 3D modeling software, multidisciplinary pulp and paper expertise, and mill management/operator communication to successfully install the fourdrinier rebuild.